During physical inspections, our technicians examine the blade closely using:

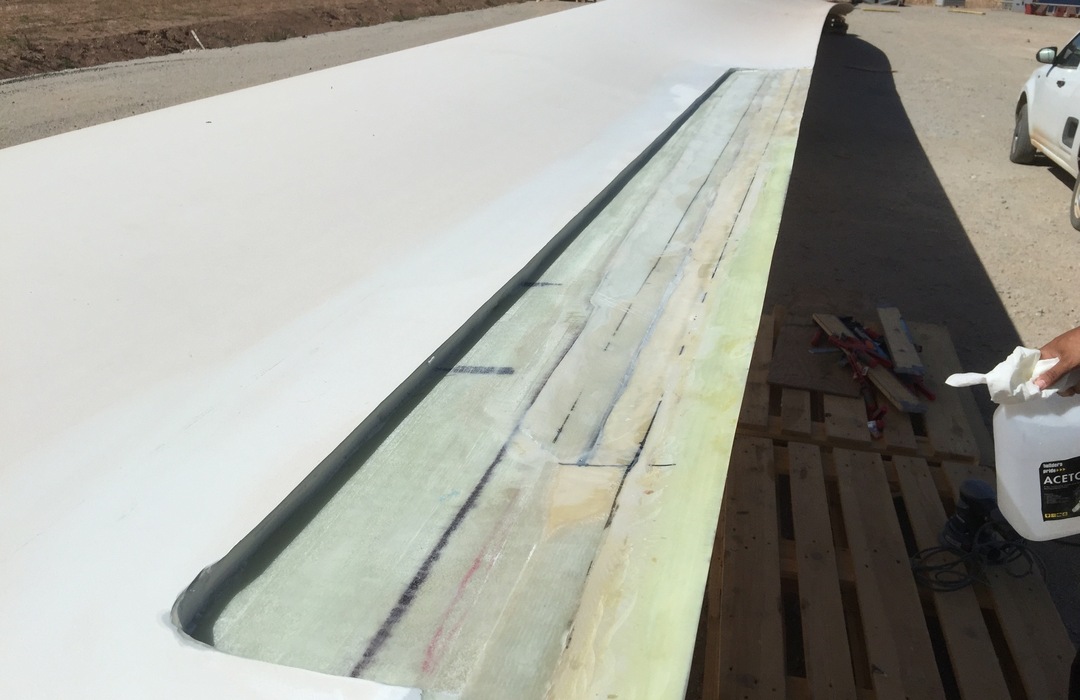

We also conduct inspections from the ground. This often involves checking blades on new construction, before installation, so they can be lifted undamaged. Ground inspections are also used for temporarily removed blades – for example, for maintenance or repair.

We also perform precise inspections remotely. For this, we use drones and high-resolution cameras:

AI-controlled drones – quickly and safely capture the blade from multiple angles.

Camera inspection – delivers sharp images for rapid analysis of visible damage.

An efficient solution for periodic checks or as an initial screening before a physical inspection.

Wind turbine blades endure a lot – both during use and in the run-up to installation. They are exposed daily to things like high rotational speeds, rain, sand, and lightning. The most common types of damage are:

Lightning damage: strikes that cause cracks or burns.

Erosion and wear: prolonged loading and extreme weather conditions cause wear on the leading edge.

Production deviations: minor manufacturing errors that can have major consequences.

Transport damage: occurs during loading, unloading, or transport.

Our role in the inspection process

Less downtime

Higher energy yield

Longer blade life

We detect any damage to wind turbine blades early and immediately provide the best solutions—for maximum performance and minimal downtime.

Choose Redak and extend the lifespan of your wind turbine blades.

We use our own and third-party cookies for statistical and analytical purposes to provide you with the best experience on our website.

More information can be found in our cookie policy